Mistakes to Avoid When Using a Single Phase to 3 Phase Converter

In many small industry settings, workshops, or business environments, it may not be easy to access three phase power. Most industrial machines are designed to run using three-phase power. To counter such a problem, a single phase to three phase converter is adopted. Such a mechanism enables the smooth operation of machines using a single phase power source. Even with the availability of such converters, some issues may arise when used improperly.

Incorrect use or improper implementation may lead to inefficient functioning and increased breakdowns of the machines being used. It is therefore important to learn from and avoid those errors in a bid to attain better efficiency and a longer lifespan. In this blog, we will understand what mistakes to avoid while using a single phase to 3 phase converter and how to avoid them.

Why Proper Usage of a Single Phase to Three Phase Converter is Important

Proper usage of a single phase to 3 phase converter is essential in the safe and efficient operation of a three phase device. Using a single phase to 3-phase converter, one can develop a reliable source of power that promotes easy functioning of a machine.

It may further lead to many other issues, like voltage imbalance issues, overheating issues, and issues related to protection devices. In the long run, these factors may increase power consumption and reduce the lifespan of motors and many other electrical devices. In an industrial environment, it may lead to unscheduled shutdowns.

Besides, understanding the importance of proper usage allows the user to make informed decisions during installation and in the process of operation; it ensures that the converter is a reliable device and not a repeated source of problems.

Mistakes to Avoid While Using a Single Phase to Three Phase Converter

A single phase to 3 phase converter operation seems so simple, yet some small mistake in selection or use may result in poor performance and damage to the equipment. Understanding these common pitfalls makes for smooth operations, better efficiency, and longer machinery life.

Incorrect Selection of Converter Capacity

In the single phase to 3 phase converter, the capacity selection will be very critical. Most users select a converter based on the simple power rating of the machine, without taking into account factors such as the starting current and load variation. As a result, it may fail to supply stable power during operation.

If the capacity is too small, tripping frequently occurs, the converter overheats, and motor efficiency becomes low. Correspondingly, a large-sized converter increases the cost without actually granting advantages. A close approximation of the converter capacity to the equipment requirements will ensure its reliable performance and prolong the equipment’s life.

Ignoring the Motor Starting and Load Requirements

Yet another frequent error involves failure to note the different loads between a motor’s starting and its normal running. Most three phase motors have a very high inrush current at startup to overcome most initial resistance. If the converter is not designed to handle this surge, the motor may fail to start properly or draw excessive current.

Ignoring or not taking proper consideration of the requirements for a motor at the time of starting will lead to more frequent shutdowns, increased heat, and long-term damage to both the motor and converter. In any case, keep in mind the conditions of the load and starting current of the motor while starting up with a view to a smooth startup and stability of operation.

Choosing the Wrong Type of Converter

Not all single phase to 3 phase converters fit each application. Due to this, some users just settle for the basic type of converter without considering the nature of the load or operating conditions. For example, static converters may be feasible with light or intermittent use, but surely not suitable for heavy-duty or continuous operations.

The use of the wrong type of converter can bring about unstable power output, reduced efficiency, and increased wear on equipment. The difference in understanding between static, rotary, and digital converters is what allows one to select the right option for reliable and long-term performance.

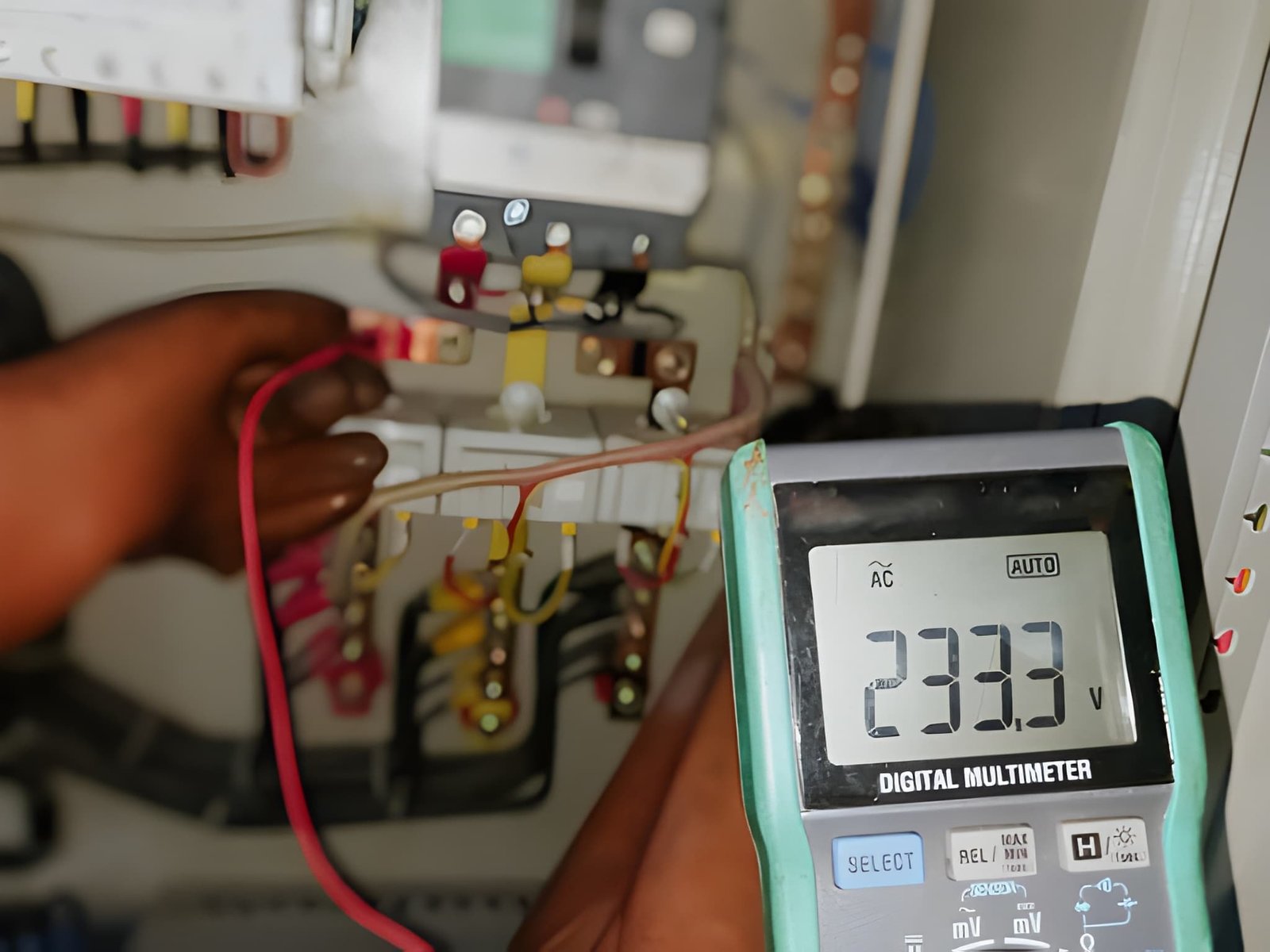

Improper Installation and Wiring

Misinstallation and miswiring contribute greatly to the poor performance exhibited by a single phase to 3 phase power converter. Inaccurate connections or imbalanced wiring could lead to the creation of voltage fluctuations or heating issues. Such issues could influence performances of the circuit or even lead to a heightened risk of electrical failure.

In case the installation is not opted for by a professional, it may lead to some safety issues and problems with the system. It is essential to correctly connect and ground the whole system in order to ensure the smooth functioning of the converter and other components.

Overloading a Converter

Exceeding the capacity of the single phase to 3 phase converter is among the most common mistakes that may affect the performance. Several machines being operated at the same time or the utilization of heavy machinery may result in the overload of the converter.

Continuous overload not only impacts the efficiency but also reduces the lifespan of both the converter and the motors connected to it. It is essential to consider avoiding overload of the converter. This will help it function properly.

Poor Ventilation and Lack of Maintenance

In most cases, users ignore or do not consider the significance of adequate ventilation while maintaining a single phase to 3-phase converter. As a result of inadequate air flow in conversion devices, they tend to become hot due to the accumulation of heat.

At the same time, failure to conduct routine inspections may result in small problems such as loose and worn-out parts, growing into huge issues. Proper ventilation and routine maintenance checks will help the converter work well and for a longer period.

Conclusion

A single phase to 3 phase converter can facilitate easy operation of three phase equipment in areas where single-phase power is available. But factors such as improper capacity selection of the converter, neglect of the requirements related to motor startup when using a three-phase equipment through a single phase to three phase converter, improper type of converter selection, improper installation of such converters, overloading, or inadequate ventilation/maintenance may directly impact the efficiency of equipment operation. We hope that now you will not have issues while converting single phase to three phase.

Also Read-Gradding Introduces AI-Powered IELTS Practice Tech for Smarter Preparation